Home

A Packaging Format's Journey

Collaboration is Essential

Elements of Recyclability

CircularityinAction.com

Recycling Education

BagandFilmRecycling.org

RecycledProductsDirectory.org

PlasticsMarkets.org

Info Exchange

Plastic Recycling Terms & Tools

Sort for Value Calculator Elements of Recyclability

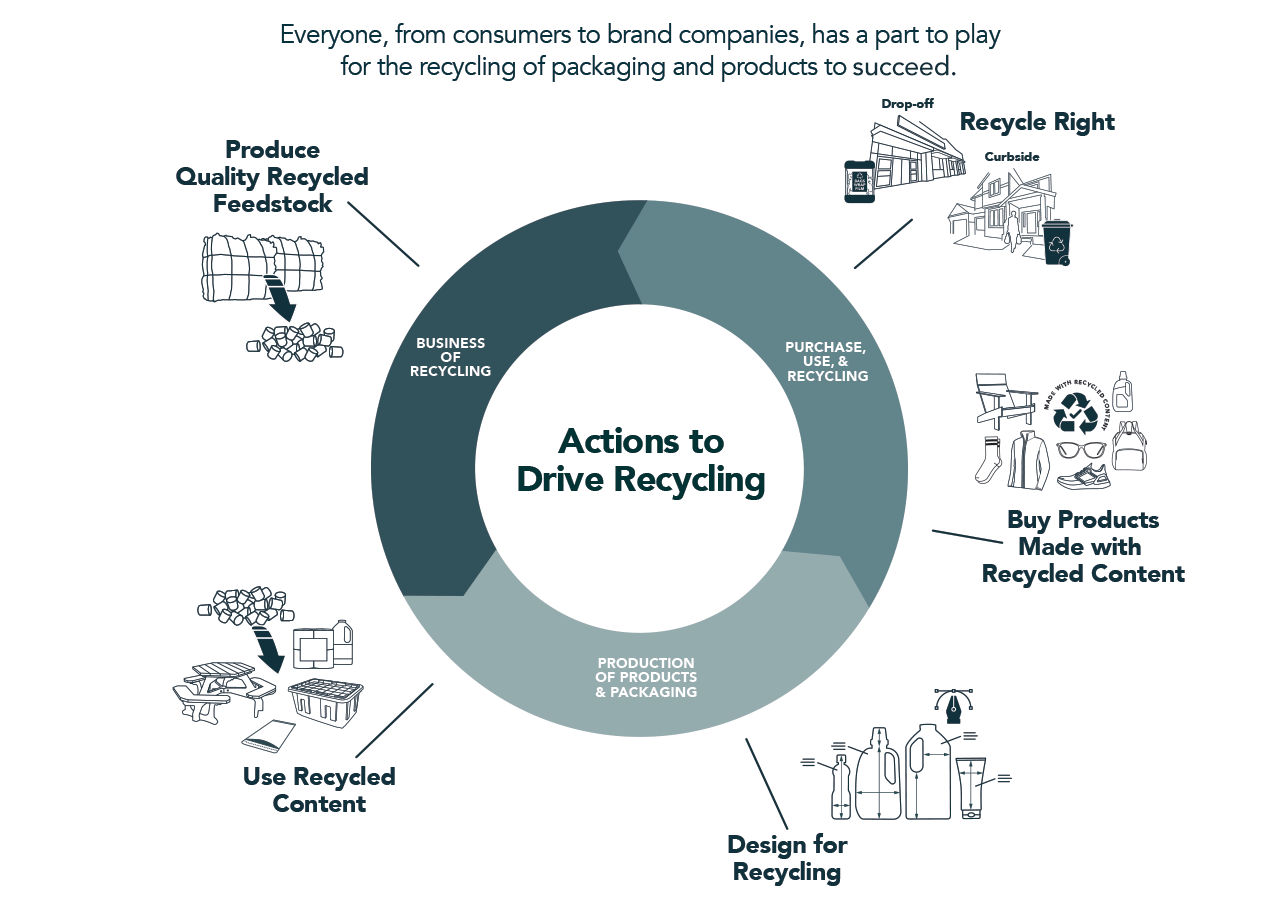

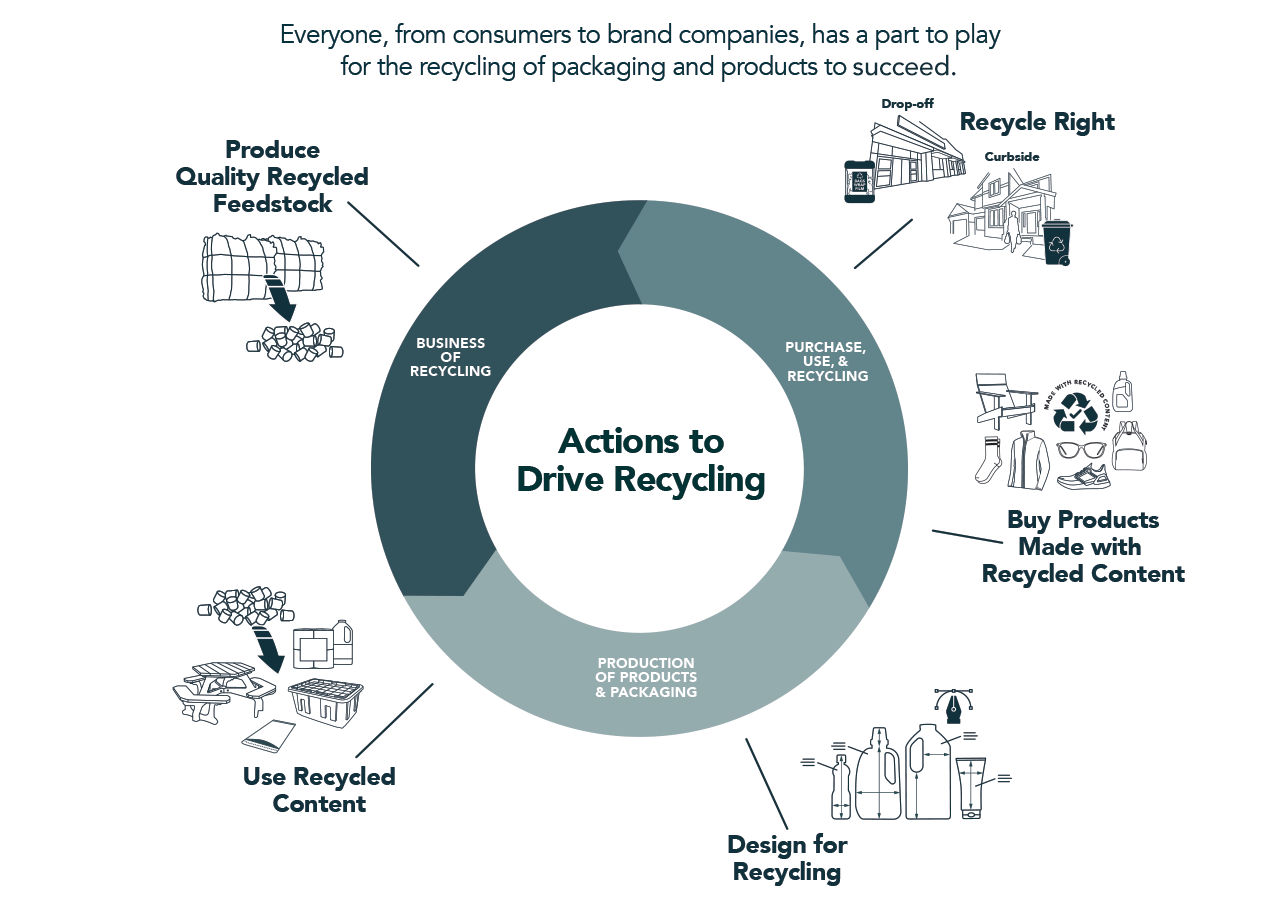

Recycling Is an Interconnected System A package or product being recyclable is just one, yet important, piece of whats needed for successful recycling. Recycling is an interconnected system and the critical steps and actions are required for successful recycling. Supply of recyclable items and demand for the recycled feedstock made from those items are essential for the economic balance of the recycling system. This balance of supply and demand comes from the actions of consumers, recyclers, producers, and sellers of products and packaging to close the loop and keep the recycling system going. This Tube Recycling Project work helps show where recyclable and recycled meet in everyday life. The Elements of Recyclability interactive slideshow below provides greater detail. Use the arrow icons to navigate through the slideshow.

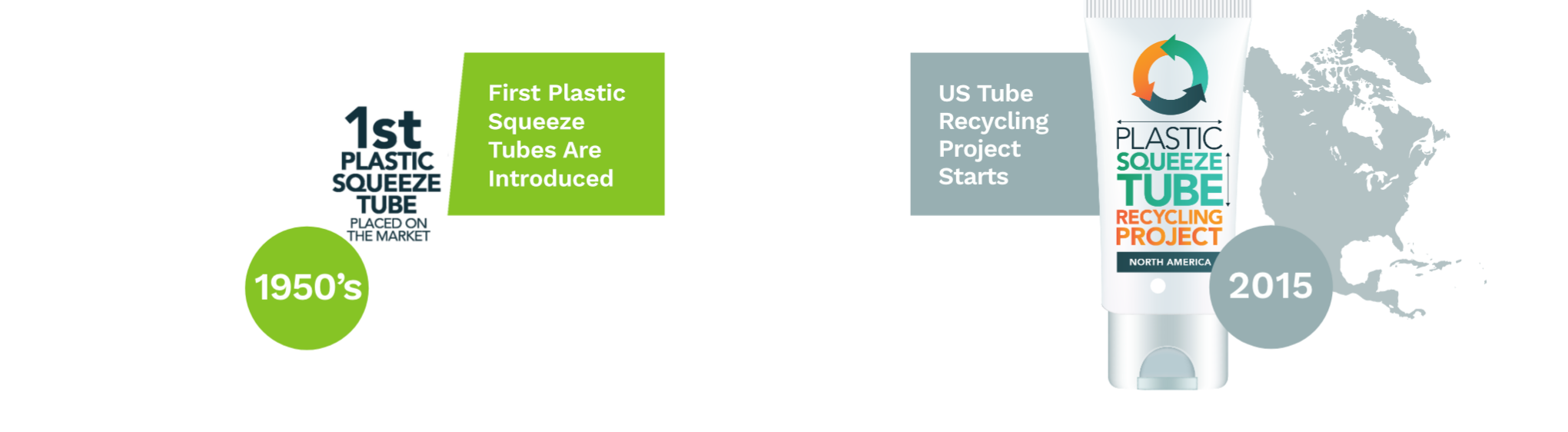

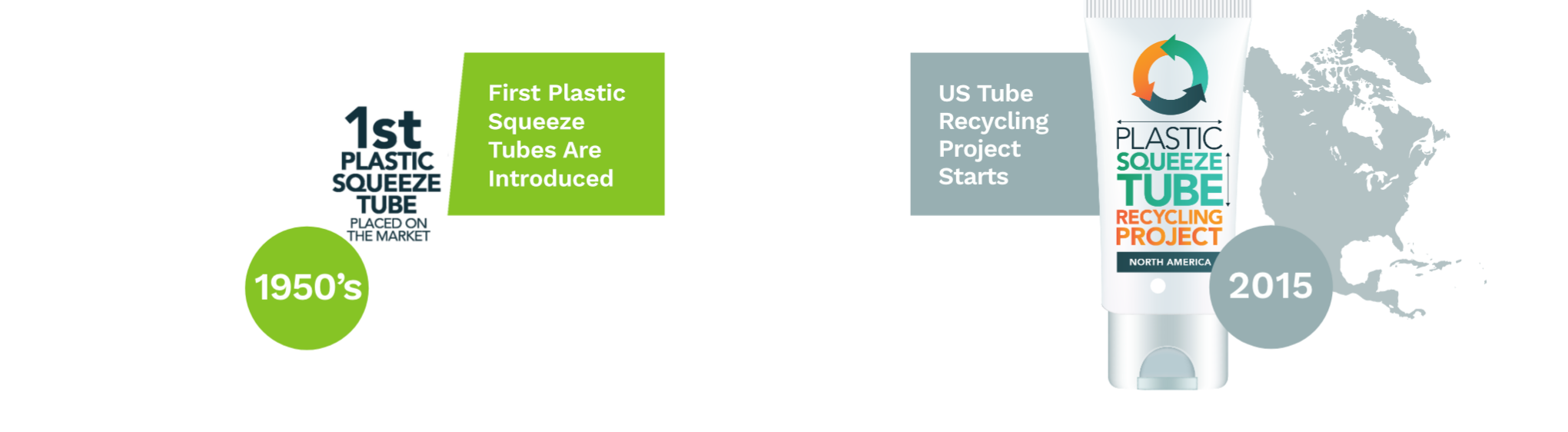

What Are the Barriers to Tubes Being Recycled? Plastic squeeze tubes are not a new packaging format. They were first introduced in 1950s. Flash forward to 2015 and there were notable questions about whether tubes can and should be recycled.

View A Packaging Format's Journey

Data from the 2015-2016 Centralized Study on Availability of Recycling showed that there was implicit acceptance of tubes, meaning that it was implied that tubes were accepted by recycling programs when they used language like Recycle Plastic Bottles and Containers. But for tubes, the technical recyclability, including compatibility with existing recycling streams, was unknown, so tubes were not considered recyclable at the time. This status and a separate effort to understand the state of play for recycling plastic squeeze tubes were the nexus of what became the North American Tube Recycling Project, primarily focused on the US. This Project has focused on understanding and working through the barriers to tubes being considered recyclable, and therefore promoted as accepted for recycling, to increase recycling of valuable material without increasing contamination.

View A Packaging Format's Journey

Data from the 2015-2016 Centralized Study on Availability of Recycling showed that there was implicit acceptance of tubes, meaning that it was implied that tubes were accepted by recycling programs when they used language like Recycle Plastic Bottles and Containers. But for tubes, the technical recyclability, including compatibility with existing recycling streams, was unknown, so tubes were not considered recyclable at the time. This status and a separate effort to understand the state of play for recycling plastic squeeze tubes were the nexus of what became the North American Tube Recycling Project, primarily focused on the US. This Project has focused on understanding and working through the barriers to tubes being considered recyclable, and therefore promoted as accepted for recycling, to increase recycling of valuable material without increasing contamination.

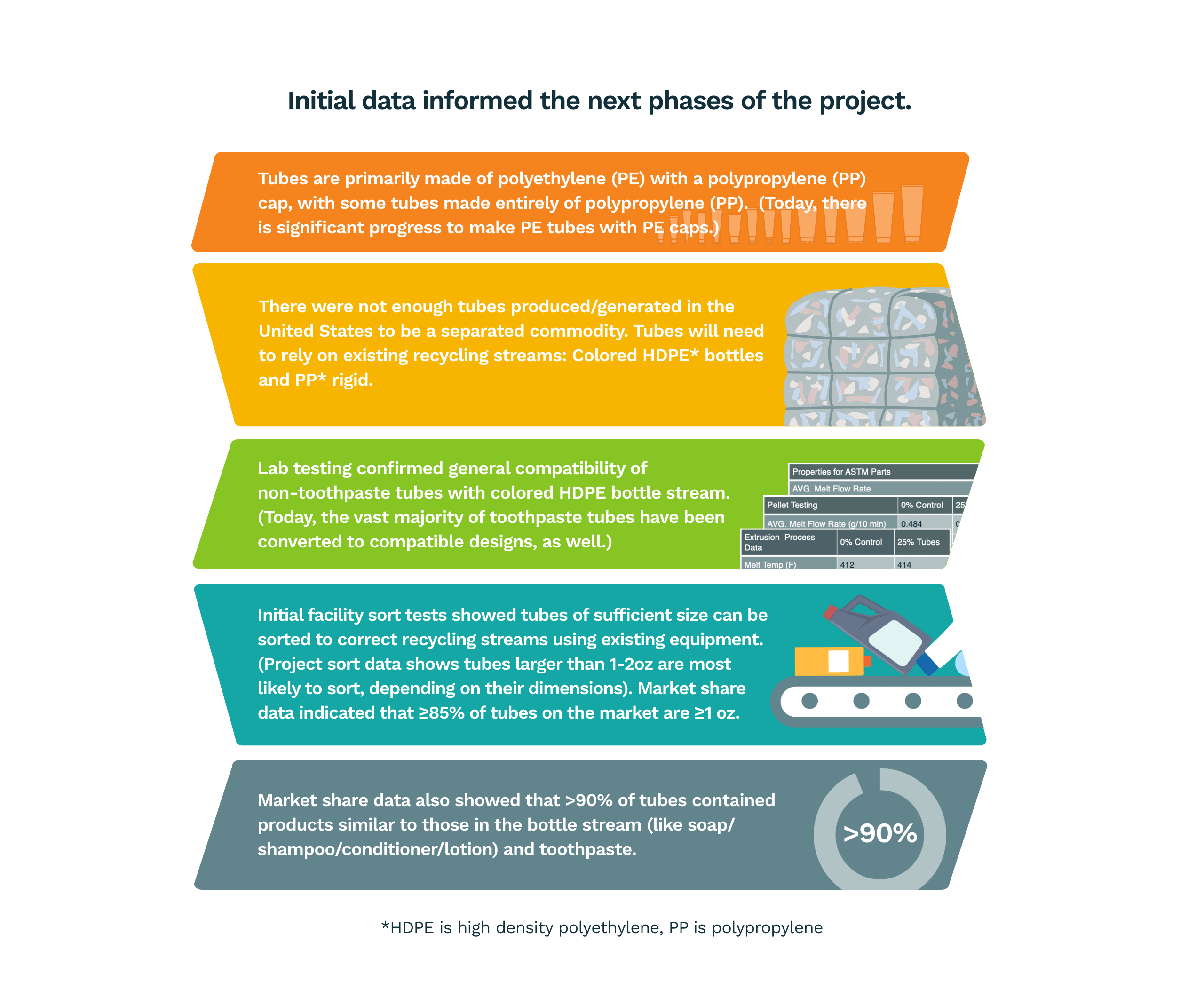

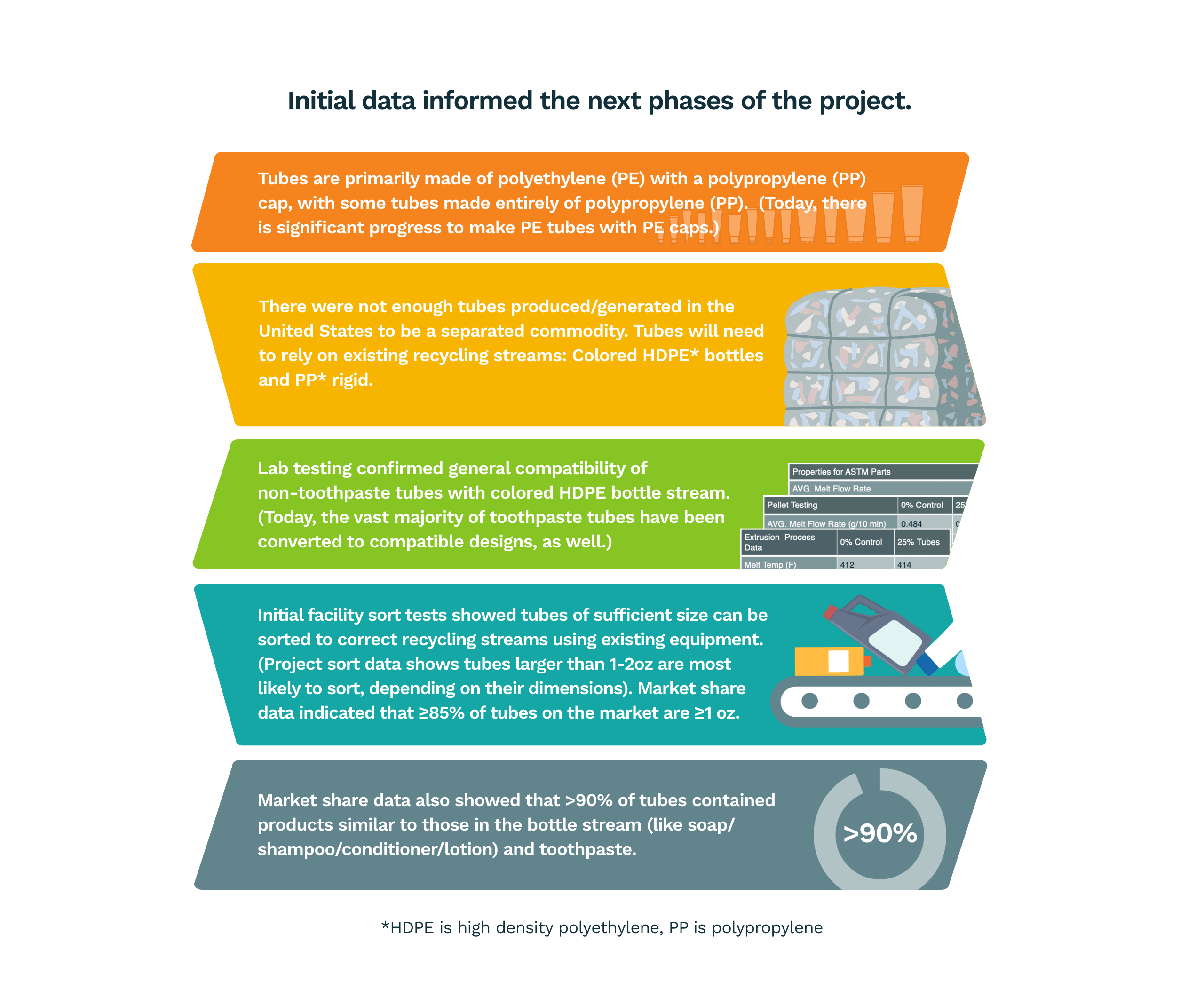

Initial Data Collection Drives Project Forward Early project work centered on gathering details about production and generation, product and size market share, compatibility, sortability and industry concerns about recycling of existing tubes.

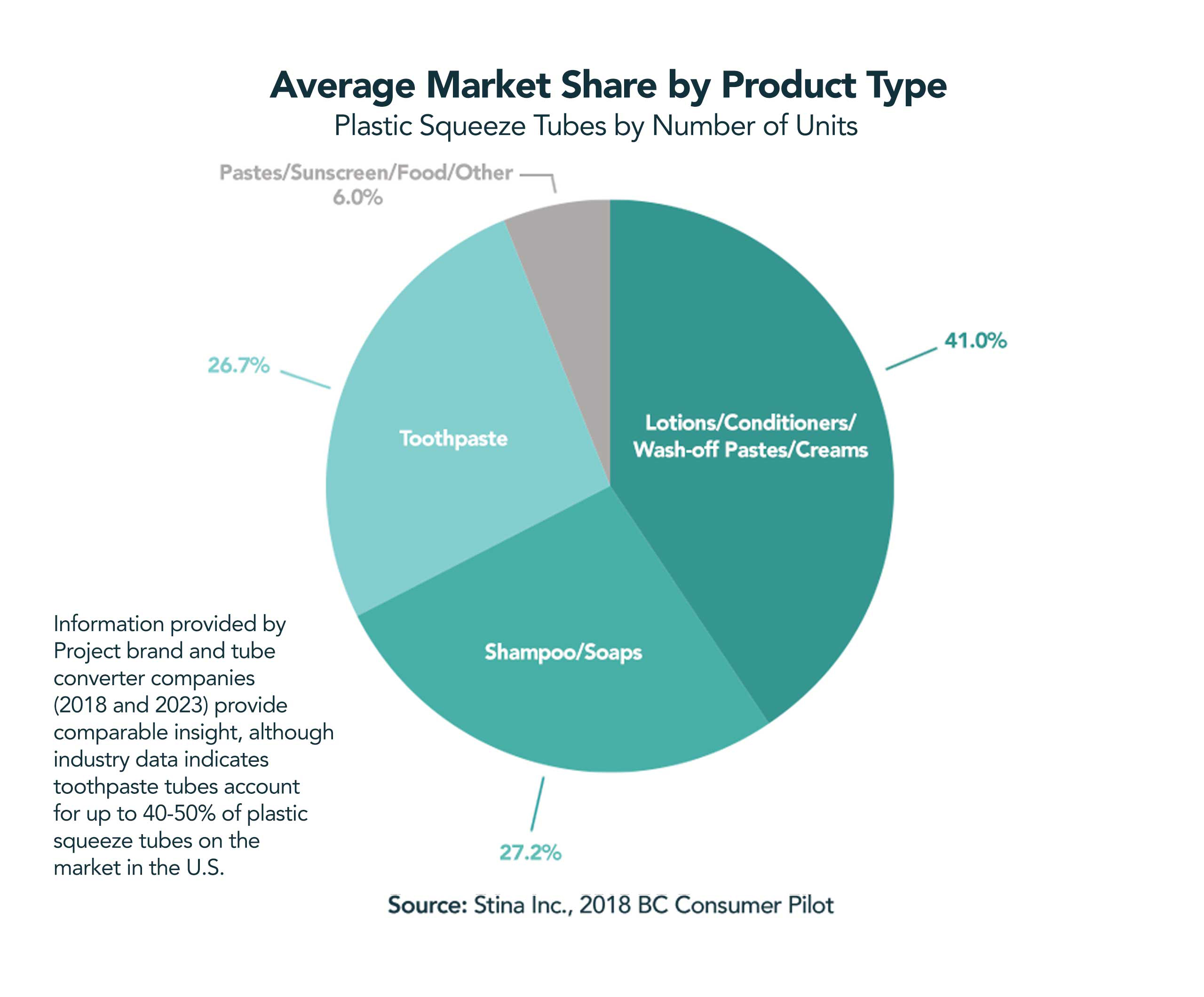

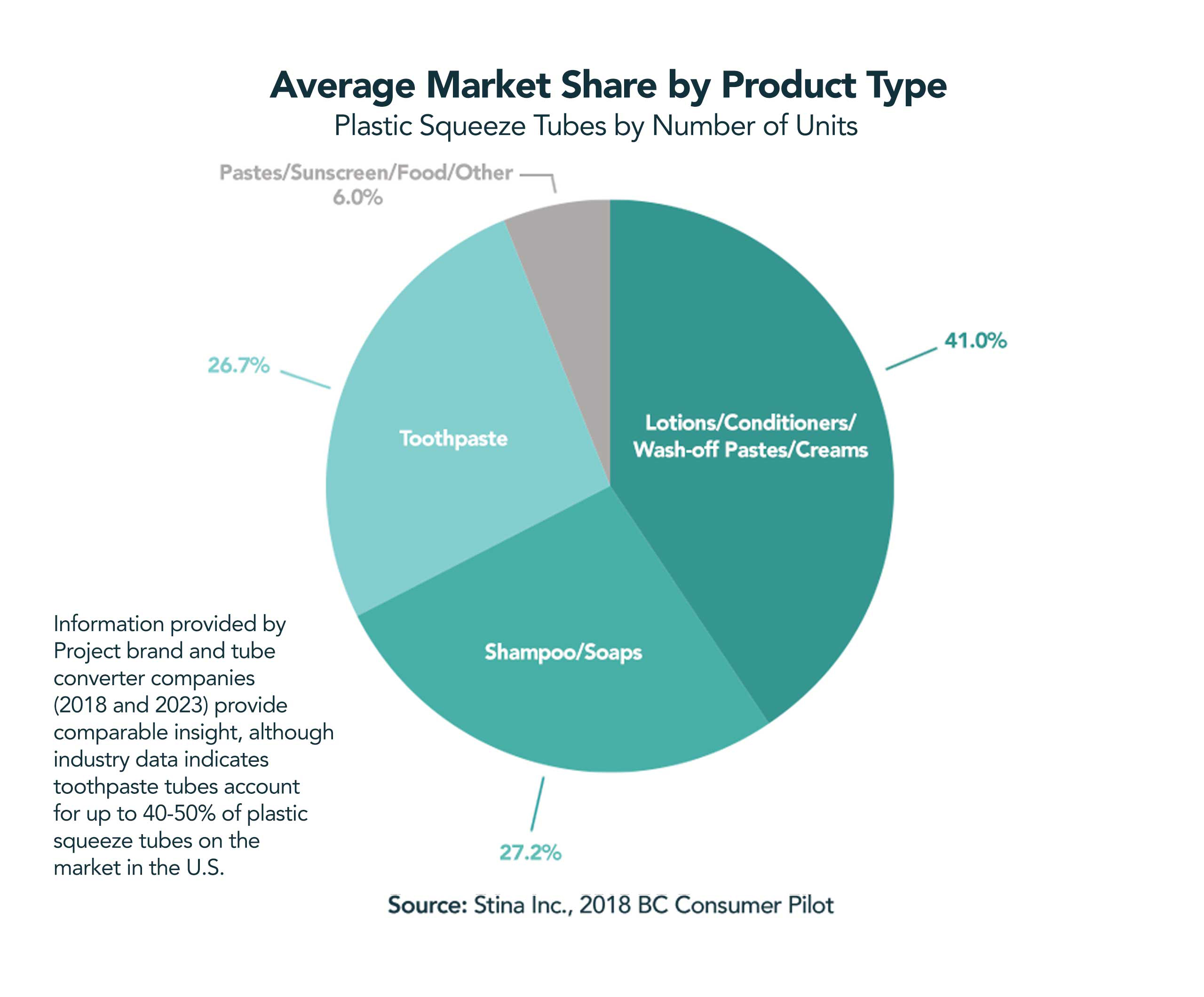

Market Share By Size Combined market share data indicate that 70% of plastic squeeze tubes are larger than 2 oz (~60ml) and 85% of tubes are larger than 1 oz (~30ml).

Market Share By Product Greater than 90% of tubes contain products like water soluble creams and soaps (similar to the bottle stream) and toothpaste.

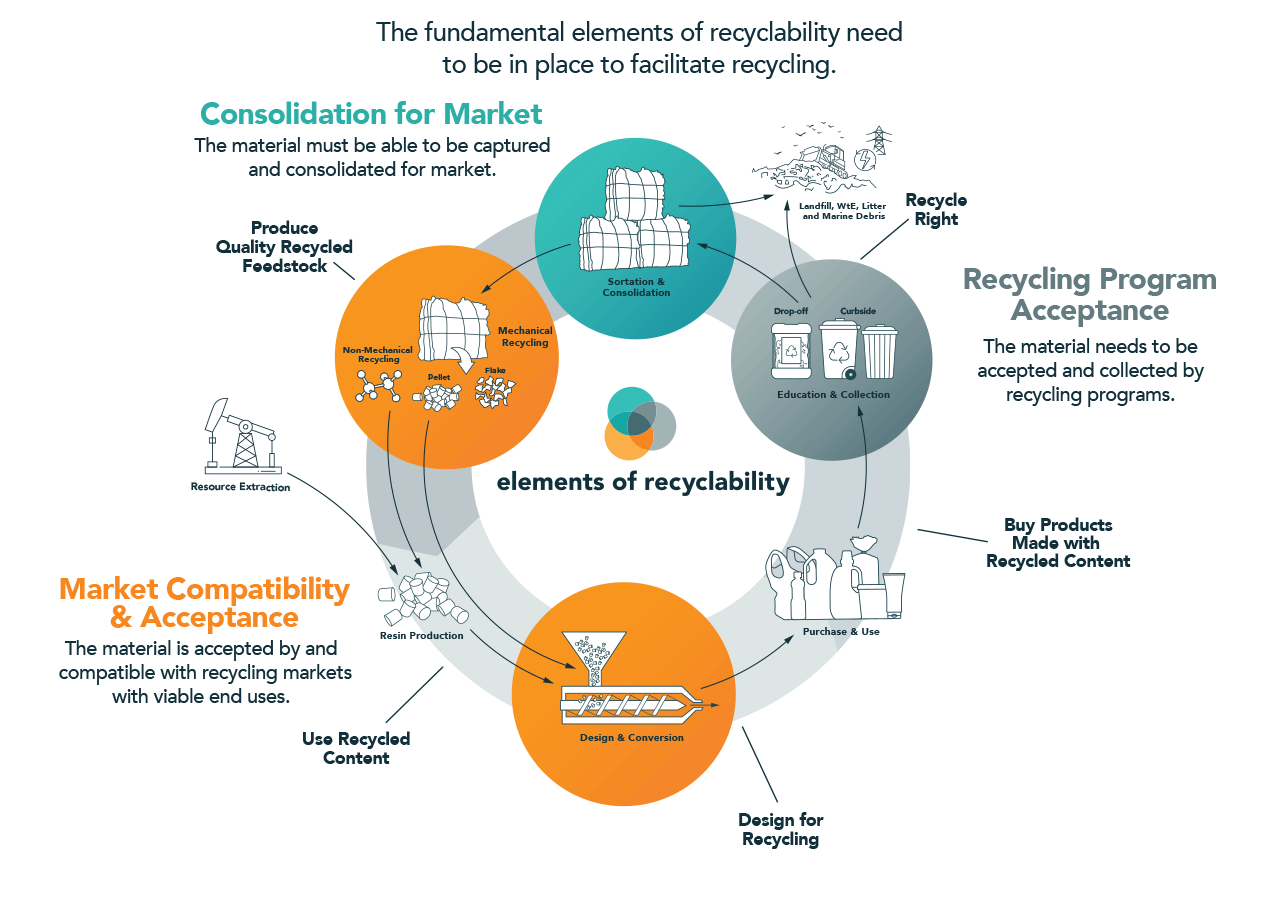

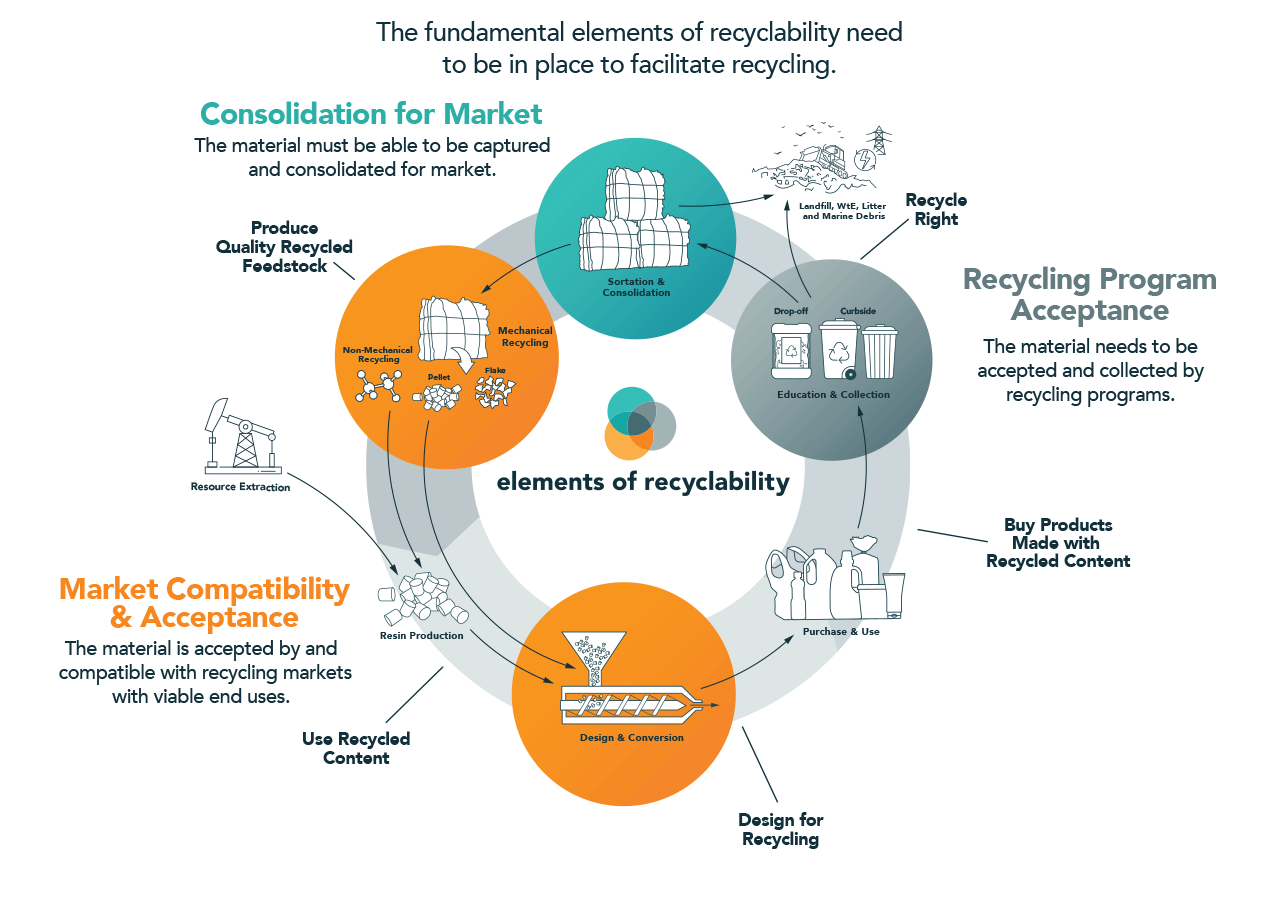

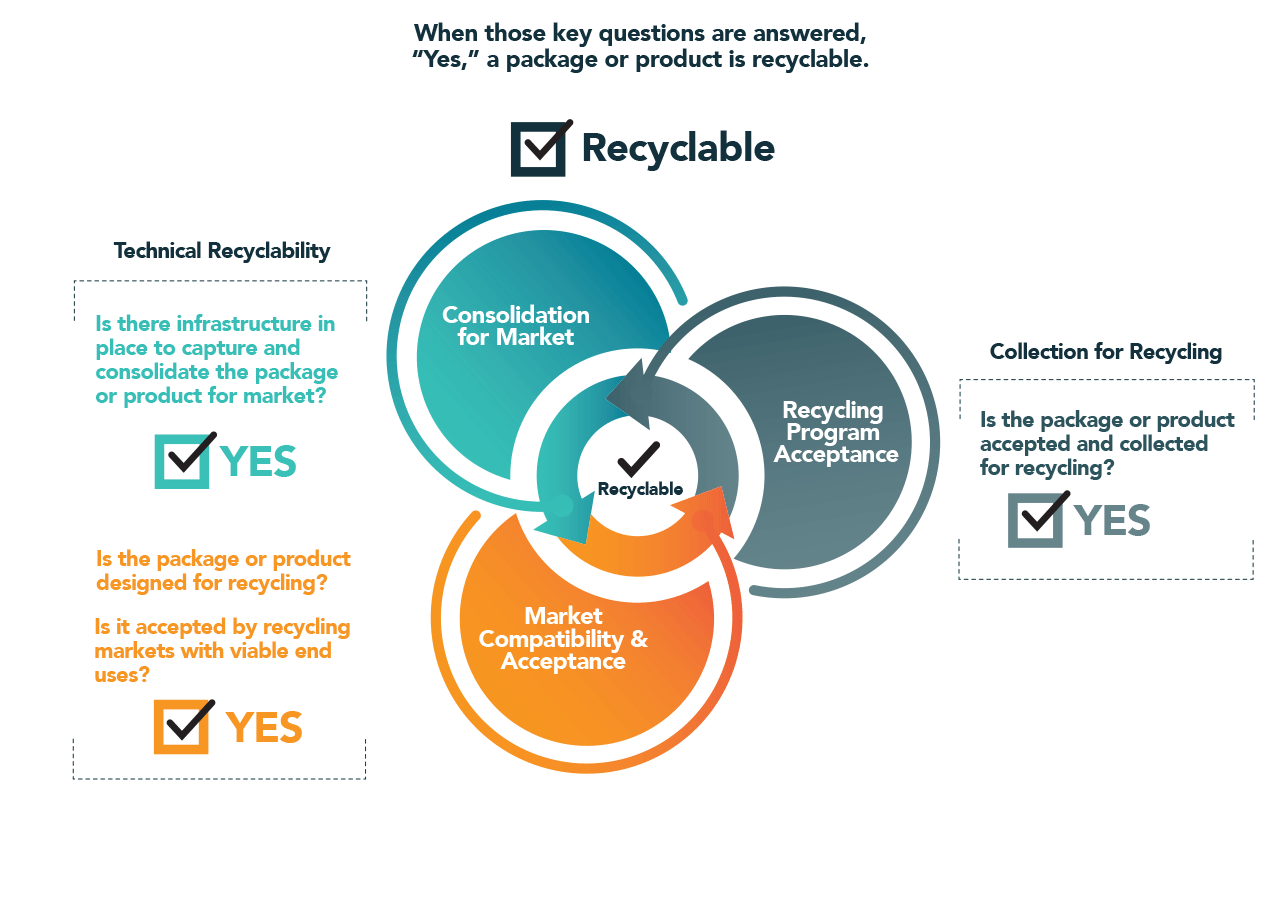

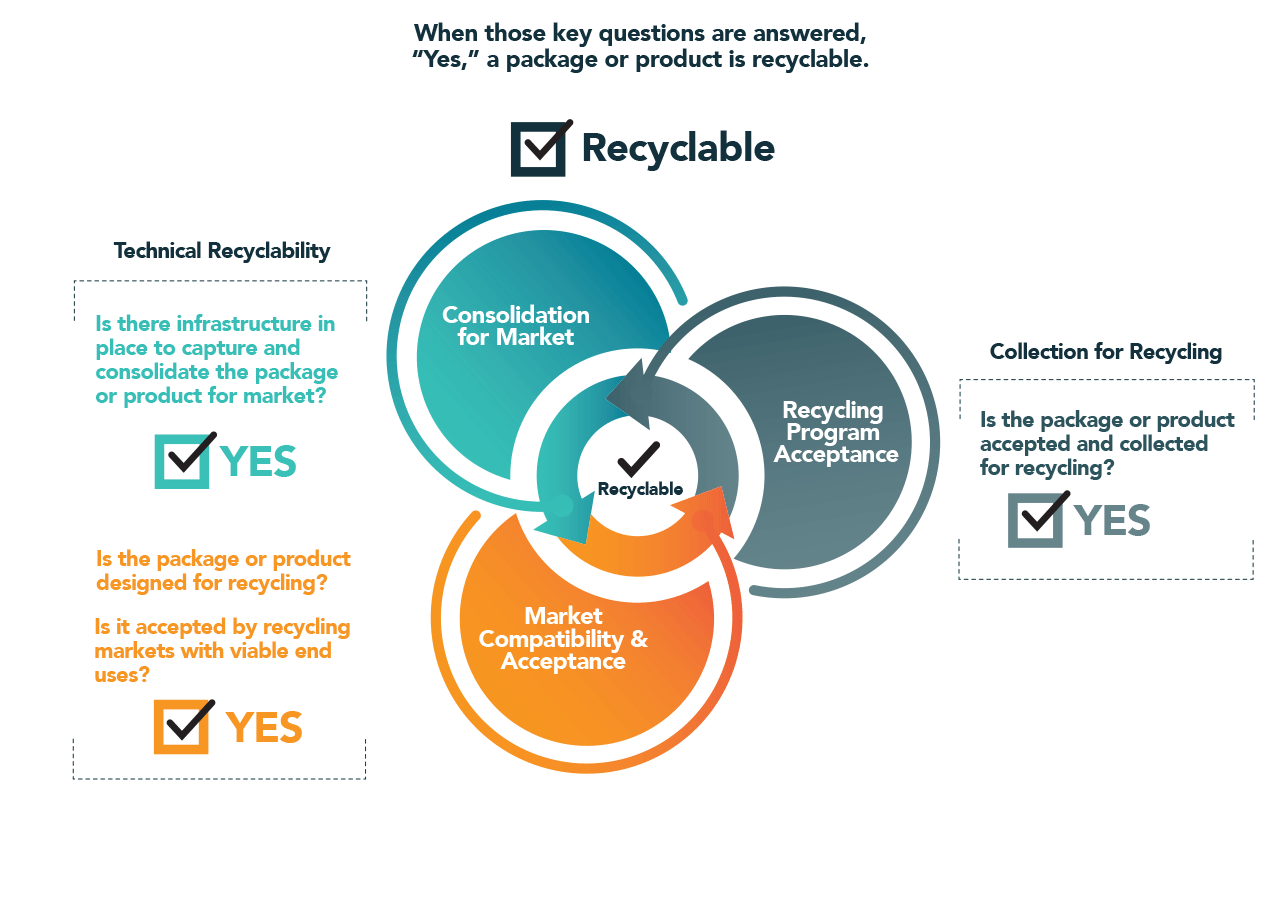

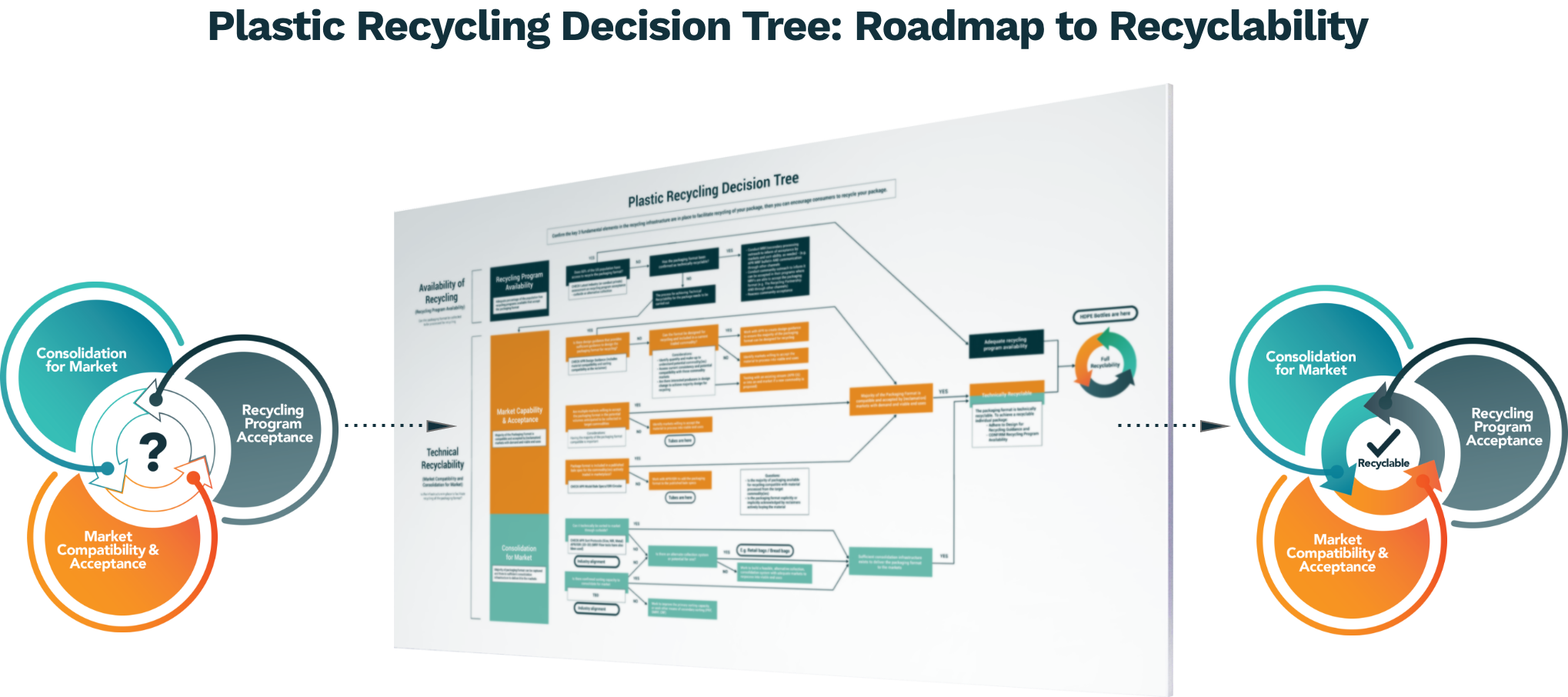

Needed a Roadmap to Guide the Efforts Along the Way We found that a roadmap to navigate the journey to recyclability for plastic squeeze tubes would be helpful in our project work, so we created a decision tree to lay out all the questions that needed to be answered. We were thoughtful of the path other packaging formats and products would also need to navigate. Our efforts allowed us to document where processes and resources were already available and where there were gaps in need of industry inputs and alignment. The key pieces in the Plastic Recycling Decision Tree are the 3 Elements of Recyclability that tubes (and any package) need to be considered recyclable: Market Compatibility & Acceptance: Designed for recycling so they are compatible and accepted by recycling markets with viable end markets that can process them into recycled feedstock, Consolidation for Market: Able to be captured by infrastructure that can consolidate them into a recycling stream that can be delivered to recycling markets, and Recycling Program Acceptance: Accepted and collected for recycling by programs so individuals know they can recycle them.

Tubes are destined for the curbside stream, but some other packaging and products may be better suited for drop-off or special collection. The decision tree allows for alternative collection programs.

Tubes are destined for the curbside stream, but some other packaging and products may be better suited for drop-off or special collection. The decision tree allows for alternative collection programs.

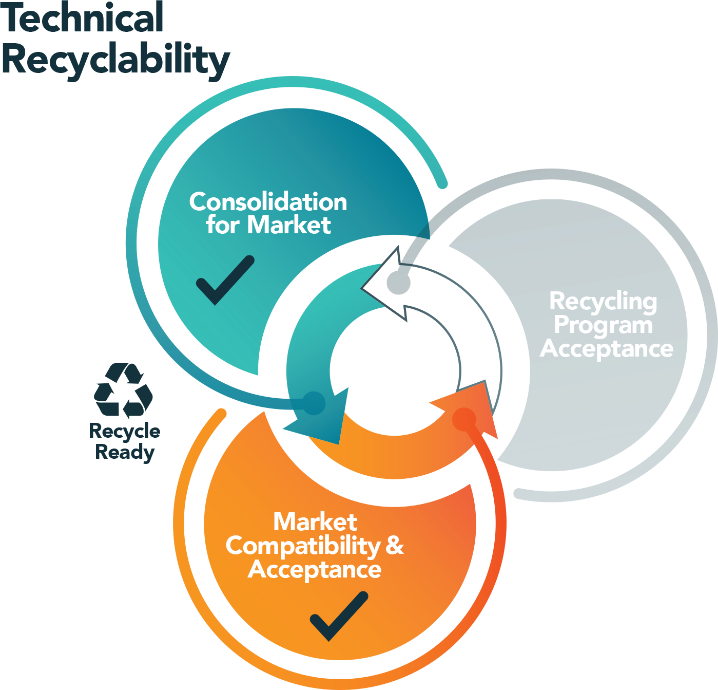

Technical recyclability (or being "recycle ready") means packages and products are designed to be compatible with the recycling stream they are destined for (Market Compatibility & Acceptance) and are able to be consolidated (sortable if collected in a commingled stream) and the infrastructure exists to consolidate the items for that recycling market (Consolidation for Market). It is essential that, not only an individual package, but the majority of the packaging format on the market is designed for recycling. This allows for clear communication to consumers, helps minimize contamination in the recycling stream and ensures recyclers are receiving valuable material to recycle. Thus, the journey for Tubes begins with design for recycling and confirming they are compatible with and accepted by recycling markets.

Technical recyclability (or being "recycle ready") means packages and products are designed to be compatible with the recycling stream they are destined for (Market Compatibility & Acceptance) and are able to be consolidated (sortable if collected in a commingled stream) and the infrastructure exists to consolidate the items for that recycling market (Consolidation for Market). It is essential that, not only an individual package, but the majority of the packaging format on the market is designed for recycling. This allows for clear communication to consumers, helps minimize contamination in the recycling stream and ensures recyclers are receiving valuable material to recycle. Thus, the journey for Tubes begins with design for recycling and confirming they are compatible with and accepted by recycling markets.

If recycling markets accept tubes as a packaging format and tubes are able to be sorted, then facilities consolidating recycled material for those markets will intentionally include plastic squeeze tubes in their recycling commodities.

If recycling markets accept tubes as a packaging format and tubes are able to be sorted, then facilities consolidating recycled material for those markets will intentionally include plastic squeeze tubes in their recycling commodities.

What It Means

Majority of the packaging format is compatible with and accepted by recycling markets, with demand and viable end uses.

How It's Achieved

METRIC Design Guidance Is there sufficient design guidance to design the packaging format for recycling?

STATUS

APR Tubes Design Resource Guide

APR Tubes Design Resource Guide

METRIC Design for Recycling Is a significant percentage of the packaging format on the market compatible with the recycling stream?

STATUS

Non-toothpaste tubes showed general compatibility in early testing by the Project. By 2023, it was estimated that at least 75% of all HDPE tubes on the US market were designs compatible with the Color HDPE (CHDPE) bottle recycling stream.

As of 2025, approximately 95% of toothpaste tubes and 85% of all HDPE tubes are compatible designs.

Learn More

Read Press Release

Non-toothpaste tubes showed general compatibility in early testing by the Project. By 2023, it was estimated that at least 75% of all HDPE tubes on the US market were designs compatible with the Color HDPE (CHDPE) bottle recycling stream.

As of 2025, approximately 95% of toothpaste tubes and 85% of all HDPE tubes are compatible designs.

Learn More

Read Press Release

METRIC Market Acceptance Are multiple markets (buyers) willing to accept the packaging format in the potential volumes anticipated to be collected in target commodities?

STATUS

With the majority of tubes on the market having recyclable designs, several reclaimers (recyclers), including KW Plastics, Advanced Drainage Systems, Envision Plastics, Talco Plastics and Denton Plastics, now accept plastic squeeze tubes in the bales of Colored HDPE they purchase. EFS-plastics also purchases bales that include tubes.

Read More

With the majority of tubes on the market having recyclable designs, several reclaimers (recyclers), including KW Plastics, Advanced Drainage Systems, Envision Plastics, Talco Plastics and Denton Plastics, now accept plastic squeeze tubes in the bales of Colored HDPE they purchase. EFS-plastics also purchases bales that include tubes.

Read More

METRIC Bale Specification Is the package format included in a published bale specification for a commodity(ies) actively traded in the marketplace?

STATUS

PE squeeze tubes were updated as a fully accepted item in the 2025 update to the Color HDPE Bottles & Select Containers bale specification, having previously been listed added as "Check with Buyer" in the the update to the Colored HDPE bale specification in 2022 version. PP Small Rigid Plastics specification includes all PP packaging and products, including PP tubes. The Small Mixed Small Rigid Plastics specification also accepts HDPE and PP packaging and products.

APR Bale Specs

ISRI Bale Specs

PE squeeze tubes were updated as a fully accepted item in the 2025 update to the Color HDPE Bottles & Select Containers bale specification, having previously been listed added as "Check with Buyer" in the the update to the Colored HDPE bale specification in 2022 version. PP Small Rigid Plastics specification includes all PP packaging and products, including PP tubes. The Small Mixed Small Rigid Plastics specification also accepts HDPE and PP packaging and products.

APR Bale Specs

ISRI Bale Specs

Parallel to work on compatibility, the project assessed issues with sortability, as the destination for tubes is curbside collection and sortation into Colored HDPE Bottle bales (or PP rigid bales).

Parallel to work on compatibility, the project assessed issues with sortability, as the destination for tubes is curbside collection and sortation into Colored HDPE Bottle bales (or PP rigid bales).

What It Means

Majority of packaging format can be captured, and there is sufficient consolidation infrastructure to deliver it to the markets.

How It's Achieved

METRIC Sortability at the MRF Can the packaging format sort at the Material Recovery Facility (MRF) to the desired commodity(ies), if collected curbside?

STATUS

Facility sort tests showed tubes of sufficient size (generally containing

1-2 oz of product and larger) can be sorted to the correct stream (Color HDPE, PP rigid, or mixed rigid bales, depending on the commodity bales that the MRF produces).

Market share data indicates 85% of tubes contain more than 1 ounce.

Learn More

Facility sort tests showed tubes of sufficient size (generally containing

1-2 oz of product and larger) can be sorted to the correct stream (Color HDPE, PP rigid, or mixed rigid bales, depending on the commodity bales that the MRF produces).

Market share data indicates 85% of tubes contain more than 1 ounce.

Learn More

METRIC Infrastructure to Sort at MRF If curbside, is there confirmed MRF sorting capacity to consolidate for market?

STATUS

The majority of tubes, made of HDPE, are destined for the Color HDPE Bottle stream that is consolidated by most MRFs in the US. PP tubes would be consolidated into a PP or mixed rigid stream, depending on the PP sorting capabilities.

The majority of tubes, made of HDPE, are destined for the Color HDPE Bottle stream that is consolidated by most MRFs in the US. PP tubes would be consolidated into a PP or mixed rigid stream, depending on the PP sorting capabilities.

In addition to technical recyclability, packages and products must be accepted for recycling by recycling programs. This is the third element of recyclability and the one that most closely involves consumers. This is the education that informs consumers that they can recycle (place in the recycling bin) a package or product in a given recycling program.

In addition to technical recyclability, packages and products must be accepted for recycling by recycling programs. This is the third element of recyclability and the one that most closely involves consumers. This is the education that informs consumers that they can recycle (place in the recycling bin) a package or product in a given recycling program.

What It Means

There are recycling programs accepting and collecting the packaging format for recycling.

How It's Achieved

METRIC Recycling Collection Programs Do consumers have access to recycling collection programs for the packaging format?

STATUS

With stakeholder engagement (reclaimers, MRFs, industry groups) on the conversion of the majority of tubes being compatible designs for recycling and positive sort data, its a good time for community recycling programs to check with your MRFs and for MRFs to check with their markets on the acceptance of tubes in bales.

If you already accept tubes, consider adding clear language and/or images to ask for plastic squeeze tubes in your community recycling program.

Downloadable Collateral

Education Support

With stakeholder engagement (reclaimers, MRFs, industry groups) on the conversion of the majority of tubes being compatible designs for recycling and positive sort data, its a good time for community recycling programs to check with your MRFs and for MRFs to check with their markets on the acceptance of tubes in bales.

If you already accept tubes, consider adding clear language and/or images to ask for plastic squeeze tubes in your community recycling program.

Downloadable Collateral

Education Support

The Journey Continues Beyond Recyclability to Recycling

As noted at the beginning, recycling is an interconnected system. Recyclability is only one, although important, part.

To increase recycling, we need to make sure that all recyclable items are collected and processed into recycled content for new products. After items are designed for recycling, the actions of Recycle Right, Use of Recycled Content in new products, and Buy Products with Recycled Content are all critical parts to create the supply and demand balance needed for recycling to be successful! The more successful we can be, the more efficiency we can achieve in the recycling system.

As noted at the beginning, recycling is an interconnected system. Recyclability is only one, although important, part.

To increase recycling, we need to make sure that all recyclable items are collected and processed into recycled content for new products. After items are designed for recycling, the actions of Recycle Right, Use of Recycled Content in new products, and Buy Products with Recycled Content are all critical parts to create the supply and demand balance needed for recycling to be successful! The more successful we can be, the more efficiency we can achieve in the recycling system.

A Packaging Format's Journey

View

A Packaging Format's Journey

View

Collaboration Is Essential

View

Collaboration Is Essential

View

Home

Managed by Stina Inc.

Connect with us on:

Connect with us on:

©2026 Stina Inc. All rights reserved. Terms & Conditions